It’s a point of pride for my wife and I about how many bicycles we have. She recently purchased a gravel grinder, bringing the grand total of bikes owned by our four-member family to 12. They include a fat bike, electric cargo bike, three kid bikes, an electric commuter, two gravel grinders, a road bike and three mountain bikes. And we want more! We tell ourselves owning bikes is a great way to save the planet because, hey, it’s not like we own 12 SUVs. But after attending a webinar by Dutch engineer Erik Bronsvoort’s recently, I’m rethinking the impacts the cycling industry has on the world.

The latest KORE Outdoors Speaker Series featured a presentation by Erik called “The Circular Revolution in the Cycling Industry & Beyond.” Erik is an engineer, author, and passionate advocate for circular design in the cycling industry. He joined the meeting virtually from the Netherlands, where he runs Circular Cycling, a consultancy dedicated to transforming the bike industry into a more sustainable and resource-smart sector. With his background in both engineering and business, Erik delivered a thoughtful and provocative talk that challenged us to rethink not just how we make bikes, but how we build the entire system that supports them.

Design for Disassembly

One of Erik’s core messages was simple but powerful: we need to start designing products with their entire lifecycle in mind. This means making bikes that aren’t just beautiful and high-performing when new, but also easy to repair, refurbish, and eventually recycle.

He emphasized the idea of designing for disassembly — using bolts instead of glue, avoiding bonded materials that can’t be separated, and minimizing the number of tools required to take a product apart. These kinds of design choices make a huge difference when it comes time to repair or recover parts. According to Erik, if you can’t take something apart easily, chances are it’s going to landfill.

From Linear to Circular

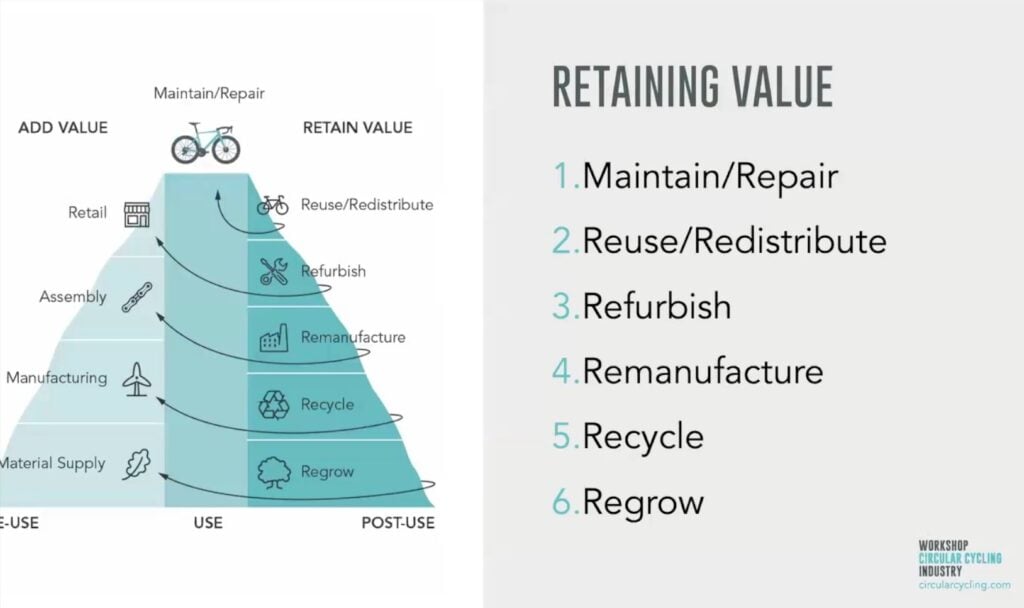

Erik explained the difference between the traditional linear economy — where we take, make, and waste — and a circular economy, which keeps materials in use for as long as possible. He described this as a mindset shift as much as a design challenge.

In a circular system, value doesn’t end with the first sale. Instead, companies can create business models around repairs, upgrades, trade-ins, and leasing. Erik gave the example of how Circular Cycling reclaims used bikes, overhauls them, and resells them with a warranty — creating new revenue from old materials and offering customers a reliable, lower-cost alternative to buying new.

Transparency and Traceability

Another major theme was transparency. Erik argued that most consumers don’t know where their bikes come from, what materials they contain, or how to properly dispose of them. Worse, many manufacturers don’t know either, especially those relying on long and opaque supply chains.

He advocated for better product traceability using digital passports or QR codes that tell the full story of a bike: where the frame was made, what alloys were used, and what service it has received. These systems can empower customers to make more informed choices and make it easier for shops and recyclers to handle end-of-life products responsibly.

Rethinking Business Models

One of the most interesting parts of the talk was about how sustainability isn’t just a moral imperative, it’s also a business opportunity. Erik pointed out that the outdoor and cycling industries often focus on marginal performance gains, like shaving off a few grams of weight, but miss the bigger picture: longevity, serviceability, and resale value.

He challenged businesses to innovate beyond the product itself. Why not offer subscription-based access to bikes, or provide trade-in credits for used parts? Why not market repairs as a premium service rather than a reluctant afterthought? These are real opportunities to build customer loyalty and extend product lifespans.

In summary, Erik Bronsvoort’s presentation was a refreshing, forward-thinking exploration of what’s possible when sustainability is baked into every part of the process — from design and materials to marketing and after-sales service. His work at Circular Cycling proves that doing better doesn’t mean doing less; it means doing things differently, with purpose and intention. For makers, designers, and gear entrepreneurs in the Kootenays and beyond, the path toward circularity may not be easy — but it’s definitely worth pedalling toward.

KORE Outdoors gratefully acknowledges the financial support of the Province of British Columbia.